Dell's pledge to "drive human progress with technology" is at the forefront of sustainable development in the electronics industry

Behind every recyclable electronic product lies Dell’s meticulous monitoring of standards, safety, and quality, complemented by detailed research and development spanning packaging, materials, and recycling processes. At the production end, often hidden from consumer view, environmental initiatives empower supplier growth, and the concept of a “community of shared interests” reinforces supply chain collaboration. Transitioning from production to consumption, from oceans to continents, and from a global perspective to a China-centric view, Dell ceaselessly challenges the limits of innovation to pioneer a responsible future.

Technology isn’t merely about sleek, cool marvels - it can also radiate/generate warmth by improving society and the environment. Since entering the Chinese market in 1998, Dell Technologies has passionately driven human progress with technology, while intertwining a deep commitment to green, circular, and sustainable practices. Whether responding to carbon peaking and neutrality goals or steadfastly pursuing long-term ESG objectives, Dell’s development trajectory has consistently been in sync with the environment and society, continuously setting industry gold standards.

Advancing together on shared values

According to the Global E-Waste Statistics Partnership, in 2019, the world generated a striking53.6 million tons of e-waste, an average of 16 pounds per capita. The twist in the tale? A mere17.4% of this mountain of waste received official recycling. If we stay this course, projections suggest a staggering 74.7 million tons of e-waste by 2030. Dell, always ahead of the curve, perceived this looming environmental shadow and rolled up its sleeves. The mission is to collect and recycle products and materials as much as possible, extend their lifespans, and invest inmaterials that prioritize recyclability, renewability, and reduced emissions. The final goal is to dial back on fresh material dependence, thus curbing waste and its associated emissions.

To companies like Dell, sustainability isn’t just a checkbox to tick off; it is a deeply ingrained commitment and cornerstone for development, much like individuals who inherently possess environmental awareness and responsibility. Liu Xiaohui, Dell’s Regulatory Engineer and Environmental Project Manager, is one such individual. Her affiliation with Dell is not mere coincidence; it’s a meeting of minds, rooted in shared values.

Liu’s decision to major in environmental science and management was no coincidental, either. Even as a child, she felt a deep sense of responsibility toward conservation. If she saw a tap running, she felt an immediate urge to turn it off – even enlisting the help of adults when she was too short to reach it herself. Witnessing wasteful use of tissue paper in public restrooms, she’d gently remind others to be more conscious. The magnet that drew Liu Xiaohui to work in Beijing, miles away from home, was Dell’s sterling environmental track record.

Take, for instance, 2014 when Dell pioneered the industry’s first closed-loop recyclable plastic supply chain. This initiative centered on reuse, repair, and recyclability, proper material choices, efficient waste plastics collection and recycling, rejuvenating plastics, and reincorporating them into components for brand-new computers. Fast forward to 2017, in a groundbreaking collaboration with the Lonely Whale Foundation, Dell innovatively fashioned plastic trays using reclaimed offshore plastics – seamlessly blending economic prudence with environmental responsibility.

During her interview, Liu Xiaohui learned about these sustainability projects. Beyond just professional skills, Dell seeks candidates who resonate with its core values. While Liu was initially impressed by Dell’s commitment to the circular economy, her admiration grew even deeper once she officially joined the team.

Beyond green: Dell’s precision in eco-friendly products

Bringing macro environmental concepts to life at the product level is about dissecting the overarching idea into tangible actions. Liu Xiaohui was taken aback not just by the duration and breadth of Dell’s eco-initiatives but by the meticulous attention to detail. She discerned that departments focusing on environmental impacts of products are intricate webs of safety compliance, product quality, and environmental standards. These standards further drill down into packaging, materials, and recycling, with dedicated individuals tracking each link.

In September 2020, Dell clinched the inaugural closed-loop plastic recycling certification from China Environmental United Certification Center (CEC), being the first certified company in China. Diving into this certification process, Liu Xiaohui grasped the rigorous detail behind each “green” Dell product.

Certification necessitated calculating the recycled plastic content within a product. Contrary to initial thoughts, this didn’t involve physically dismantling products in labs to measure plastic content, given the material consistency of plastics, old or new. Instead, Liu needed to compile a robust evidence chain. Astonishingly, every recycled product came with documentation akin to a “household registration booklet,” meticulously listing parts made of recycled plastics, their compositions, and serial numbers. This intricate evidence chain reflected Dell’s every endeavor in championing the circular economy.

Drawing from its existing eco-practices, Dell has revisited, researched, and revamped every phase of product life, ushering in a revamped closed-loop model spanning “use-recycle” to “use-reuse-recycle”.

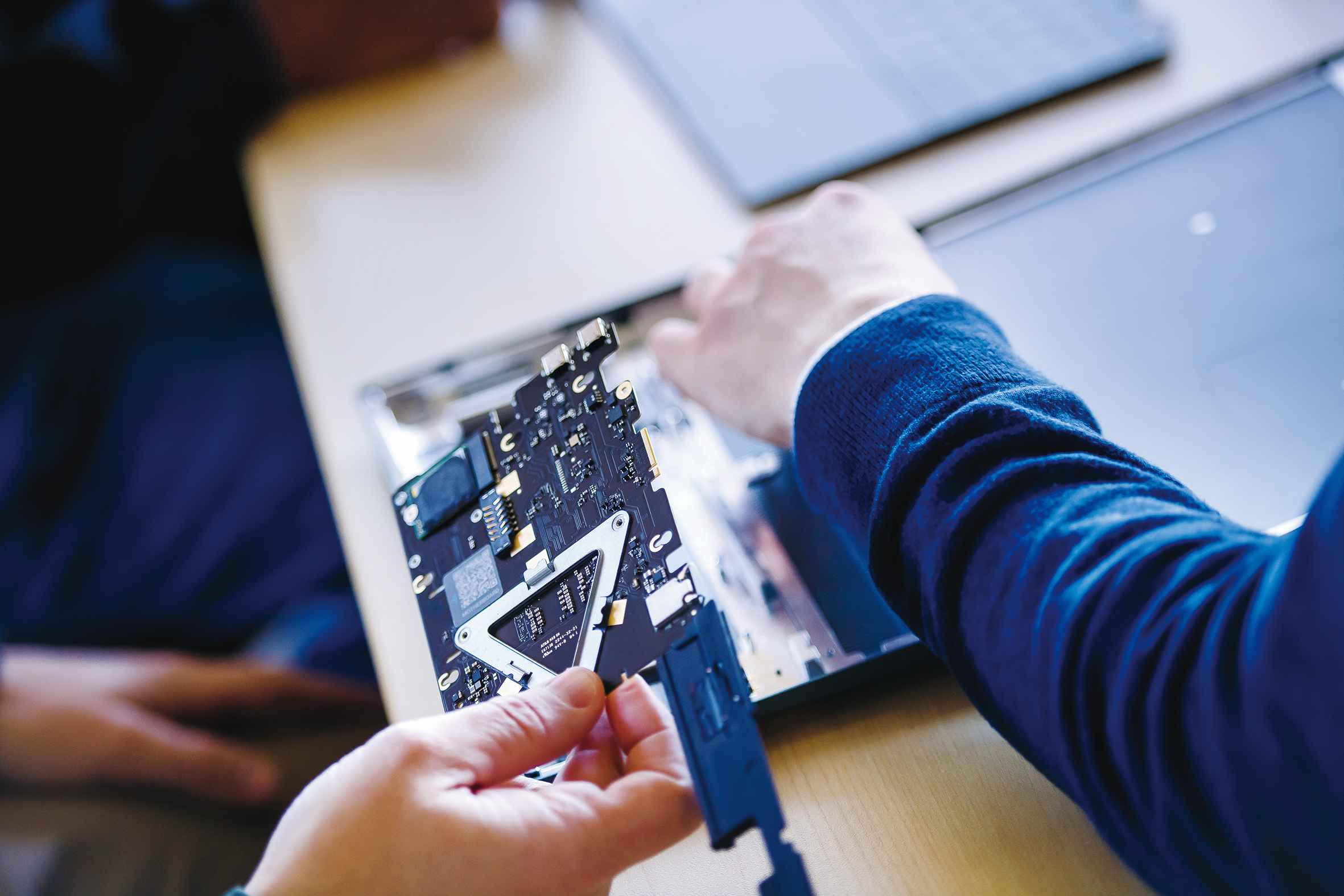

In the product design phase, Dell is driven to create products that stand the test of time - durable, repairable, and recyclable. In FY 2022, Dell unveiled “Concept Luna,” a beacon of revolutionary PC designs. Highlights include a striking 90% reduction in screw use, making internal component upkeep a breeze; adhesive-free modular design; a motherboard miniaturized by 75%; an aluminum chassis crafted via hydroelectric power, minimizing energy use and waste; and advanced deep-cycle batteries engineered for efficiency and refurbishment post their inaugural product run.

This ceaseless drive to push innovation boundaries is quintessentially Dell.

Unseen efforts: Beyond the consumers’ gaze

Behind the scenes, in areas untouched by consumer hands like the production end, Dell is also making substantial strides.

In the past year, significant green renovations were undertaken at Dell’s factories in Chengdu and Xiamen, marking a pivot towards more extensive renewable energy applications. A notable endeavor is Dell’s standalone solar energy project at the Xiamen plant. As of now, it stands as the most expansive rooftop distributed photovoltaic power project on Xiamen Island, backed by a ten-million RMB investment. In June 2023, the plant’s second photovoltaic power phase was successfully completed and put into operation. This augmentation allows the plant’s standalone solar output to touch an impressive 3.88 million kWh annually, slashing carbon dioxide emissions by 2,500 tons each year. In tandem, the Xiamen facility achieved a significant energy overhaul, introducing an advanced energy monitoring system and a double-layered roof, realizing annual energy savings of 290 MWH.

Self-improvement isn’t Dell’s ultimate goal. Building a more encompassing circular economy necessitates collaboration across the entire industry chain. Thus, Dell birthed a division dedicated to global supply chain socio-environmental responsibility, to holistically green the supply chain. This entails bolstered green supplier management, enhanced eco-friendly production,establishing a sustainable recycling framework, and setting up a comprehensive green information platform for data collection, oversight, and dissemination.

In China, Dell adopts a whole-chain perspective, kindling in-depth synergies with both upstream and downstream entities. From raw material sourcing, processing, and packaging to storage, transportation, use, and end-of-life disposal, the aim is optimal resource utility with minimized consumption and ecological footprint, to protect the environment, save energy, and cut emissions. Under this umbrella, Dell has rolled out a slew of supply chain eco-initiatives – focusing on energy efficiency enhancement, water risk mitigation, zero-waste land- filling, and supply chain eco-maps – to elevate its supply chain’s environmental performance and influence from various aspects.

Zhao Feng, a Dell supply chain management veteran of 9 years, is intimately familiar with these green initiatives. With a background in safety engineering and an even split of his career across manufacturing and brand-side roles, joining Dell shifted his problem-solving paradigm. He likened his earlier approach to pinpoint precision but, at Dell, it’s broad strokes. Zhao reflected, “Assessing issues brand-side, the ripple effects span the entire supply chain. A single initiative might resonate across dozens, perhaps hundreds of factories. Take, for in- stance, Dell’s push for water or energy conservation; within one program, numerous facilities might simultaneously champion these efforts.”

Cultivating an ecosystem: Dell’s “community of shared interests”

Zhao Feng candidly admitted that constructing a green supply chain presented an array of unanticipated challenges, especially in communication. Recounting an episode where the initiative was to replace conventional lighting with LED solutions in the supply chain, he high- lighted the resistance from smaller factories. These establishments balked at the upfront costs of an LED overhaul, questioning the short-term return on investment. “For these small to medium-sized factories, the transition costs felt overwhelming and the immediate returns, not so enticing, which dampened their enthusiasm for the initiative,” Zhao recollected.

In the face of such resistance, Zhao’s role wasn’t just to pinpoint the issue, but also to architect feasible solutions. He recognized that for energy-efficient endeavors to gain traction, the financial constraints of these suppliers had to be acknowledged. A brainstorm with his team led to a collaboration with a third-party firm, in search of an innovative cooperation model with win-win outcomes for multiple parties.

After negotiation, this third-party entity agreed to foot the bill for the LED retrofitting, and in turn, the savings garnered from the factories’ reduced electricity expenses would reimburse them per the contract terms. As a result, factories enjoyed energy savings without added costs, the third-party secured a new revenue stream, and Dell’s eco-vision for its supply chain took a decisive step forward.

For Zhao, scenarios like these have become commonplace. His role frequently shuttles him between different supplier factories. He ropes in experts from the energy and environmental domain to conduct in-depth onsite assessments, pinpointing opportunities to augment resource and environmental management efficiency. Tailored recommendations are made, keeping the factories’ unique conditions in focus. As a token of appreciation and motivation, suppliers exhibiting exemplary cooperation and outcomes receive an elevated score in Dell’s quarterly business performance reviews. This nudge from the business end to the production end motivates suppliers to evolve – from being transactionally driven to adopting Dell’s green ethos at their core.

“Undoubtedly, spearheading such initiatives can be daunting, consuming immense resources and energy. Yet, the endeavor is indispensable, for we perceive our suppliers not merely as external entities but as integral members of a shared interest community,” Zhao emphasized.

He cited an illustrative example: While Dell isn’t directly accountable for suppliers’ safety mishaps, the company still dedicates resources to train them on safety and occupational health.Dell’s commitment aids factories in preemptively spotting and addressing safety hazards.

This “community of shared interests” concept, coupled with a multitude of capacity building initiatives steered from the supplier’s perspective, has reshaped Zhao’s perception. He no longer views his communication with suppliers as a conventional client-service provider dynamic. It’s a true partnership. This shift has also cultivated in Zhao a deeper empathy, fueling his intrinsic motivation to uplift and assist supply chain partners.

Championing a green future: Dell and the broader community

In its Chinese operations, Dell has forged a partnership with the Platform for Accelerating the Circular Economy (PACE) and jointly initiated a pilot project focusing on closed-loop plastic recycling. This move aligns with China’s ambitious targets: achieving a 50% e-waste recycling rate and ensuring that 20% of product material procurement is recycled by 2025. Dell’sFY2023 ESG report underscored remarkable achievements: the company used 155.5 million kilograms of sustainable materials for its products and packaging; 94.5% of its entire product portfolio’s packaging came from recycled or renewable materials; and since 2019, 39.2million plastic bottles had been kept out of the ocean.

Due to these environmental achievements, Dell garnered a multitude of green and sustainability awards, both globally and in China. Compiling and declaring these awards falls within Liu Xiaohui’s responsibilities, and she considers it the most rewarding aspect of her role. In 2021, Dell’s pioneering sustainable packaging solutions were honored with the 2021 Golden Key·Excellence award at the “GoldenKey——SDG Solutions,” organized by China Sustainability Tribune. Liu Xiaohui, representing Dell, delivered a presentation during the roadshow and the advancement rounds.

The memory is still fresh for her. Though well-prepared, nerves hither on stage, as she realized that she wasn’t merely representing herself. Behind her, there was Zhao Feng from the green supply chain division and colleagues from various departments — some familiar, others strangers — all united in their shared commitment to Dell’s sustainability vision.

Looking back, Liu Xiaohui fondly recalled, “I am the lucky one. The strides we’ve made in environmental preservation are the result of collective dedication and brilliance from colleagues across various departments. Many engrossed in their individual tasks seldom get the chance to witness the broader achievements. Receiving the award was a thrilling moment for me. I felt that, while my contribution might be a mere fraction of the whole, it’s still invaluable.”

Looking ahead, Liu Xiaohui is poised to embark on a fresh venture, focusing on the recycling and reuse of metals. Zhao Feng, on the production end, remains committed to his relentless engagements with suppliers, contemplating strategies to amplify the project’s reach and engage a more extensive network of supply chain partners.

Back at Dell’s headquarters, the aspirations are clear and bold: “By 2030, 100% of our packaging will be made from recycled or renewable material, or will utilize reused packaging; more than half of our product content will be made from recycled, renewable or reduced carbon emissions material; our customers and partners will rate Dell Technologies as their most trusted technology partner.” These solid ESG targets epitomize Dell’s reverence for nature and its staunch pledge to “drive human progress with technology”.

Back

to top

Back

to top