Reviving latent electric energy through a “virtual power plant” to illuminate the path to urban development’s future.

In Pinghu, a city driven by industry in Zhejiang Province, growth was once hampered by electricity shortages. However, an “invisible” power plant subtly turned the tides. By harnessing every available unit of energy and utilizing peak shaving and load shifting, State Grid Pinghu Power Supply Company leverages controllable load resources on the demand side through the virtual power plant (VPP) model, unleashing dormant energy potential. A new type of power system based on new energy sources is energizing production lines across diverse sectors and lighting the way to the future of urban development.

Situated along the East China Sea coast, Pinghu City in Zhejiang Province ranks as one of China’s largest hubs for manufacturing automobile parts. The local automotive industry boasts an annual output value exceeding RMB 40 billion. Under the influence of prominent automakers like Great Wall Motor, it has established a comprehensive industrial ecosystem known for the unique distinction of “All vehicle components being manufactured in Pinghu” .This reputation extends not just within Zhejiang, but across the entire country.

However, Pinghu, a county-level city that prospers thanks to its auto parts industry, once confronted a critical challenge: the rapid growth of its industrial sector was restrained by an inconsistent power supply.

Electricity, as widely understood, operates on an immediate balance principle – power plants generate electricity in response to user demand. This equilibrium is maintained by the power grid. While power plants continuously generate electricity round the clock, electricity demand fluctuates, with higher consumption during the day and lower at night, as well as variations between seasons, peaking in summer and winter and declining in spring and autumn. Relying solely on power plants to adapt electricity generation to shifting demand not only escalates operating costs but also threatens a stable power supply. In recent years, China has made significant strides in the development of renewable energy, such as wind and solar power. The widespread adoption of these new energy sources can effectively contribute to achieving the goals of carbon peaking and neutrality. However, the intermittency, variability, and instability associated with weather-dependent energy sources present substantial challenges to the overall security and reliability of the power grid.

Pinghu is among the pioneering low-carbon pilot counties in Zhejiang, with a leading portion of electricity derived from wind and solar energy within the province. Nonetheless, Pinghu also frequently encounters an unstable power supply during the peak-demand seasons of summer and winter. This instability significantly impacted the industrial sector. In 2022, Pinghu implemented a 19-day period of regulated electricity consumption, which greatly affected 57 automotive companies. Speaking of this episode, the manager of the Pinghu plant of Kautex, one of the world’s top 100 automotive suppliers, can still recalls his anxiety at that time. In less than three weeks, the daily electricity consumption at Kautex’s Pinghu facility dropped to 2,300 kWh, merely 13% of the regular usage. Such a significant reduction in power supply presented production challenges, resulting in delivery delays and disrupting the smooth operation of the local supply chain and economic revenues.

At present, the government management of enterprise electrical loads is not detailed enough. The absence of data on enterprise electricity usage can undermine decision-making effectiveness, resulting in “disorderly” electricity consumption. How can we address this challenge and guarantee a stable power supply for businesses during peak electricity demand periods? The solution, put forth by State Grid Pinghu Power Supply Company, is the establishment of a virtual power plant.

Maximizing electrical power efficiency

For many, the mention of power plants evokes images of towering chimneys, colossal structures, billowing smoke, and a complex network of high-voltage lines. However, the virtual power plant in Pinghu, Zhejiang, stands in stark contrast. It operates without the infrastructure typically associated with power generation, doesn’t burn coal or gas, and yet, it still effectively regulates electricity.

A virtual power plant, often referred to as a VPP, is a system that uses information technology and smart devices to manage and regulate variable energy sources. It integrates and controls dispersed elements, including power sources, grids, loads, and energy storage to create a large-scale “power bank”. It possesses the capability to operate as a “positive power plant,” supplying power to the system, or as a “negative power plant,” absorbing surplus power from the system. Hence, it plays a versatile role in peaks having and load shifting.

Take Seazen Wuyue Plaza in Pinghu’s Nanshi New District as an example. Within this commercial complex, multiple air conditioning units are in operation. During peak electricity demand in the summer, if remote control can be achieved through VPP controllers, raising the central air conditioning’s temperature by 2 to 3 degrees Celsius can effectively reduce the air conditioning load by about 10%, cutting almost 20% of daily electricity consumption. The “saved” electricity can then be distributed to areas with greater power needs, alongside surplus power from other electricity consumers.

Pinghu hosts Zhejiang Province’s inaugural county-level “source-grid-load-storage integrated” VPP pilot. Since the end of 2020, State Grid Pinghu Power Supply Company has been spearheading the VPP’s development with the backing of State Grid Zhejiang Electric Power Co.,Ltd. The initial beneficiaries of the VPP’s advantages are notably large industrial enterprises,particularly automotive companies, which have substantial electricity consumption.

Ensuring power supply to corporate users through peaks having and load shifting

Entering the general assembly workshop of Great Wall Motor’s Pinghu branch, modern automated production lines, which encompass the interior production line, chassis assembly lines, and vehicle assembly line, were operating seamlessly. However, at that very moment, an uptick in power load of the supply line occurred. Once the demand was confirmed, the chief commander at the control center of State Grid Pinghu Power Supply Company’s VPP platform swiftly formulated user execution strategies based on resource allocation, main transformer line sensitivity, and historical performance scores. These strategies were then promptly communicated to the corporate user.

Upon hearing the buzzing sounds, the electricians at Great Wall Motor promptly inspected the VPP’s interactive terminal and activated the confirmation button on the terminal interface. Adhering to the strategy provided by the main station, they temporarily deactivated certain auxiliary equipment without causing any production disruptions, thereby creating a load reduction capacity of 1000 kW for load regulation.

Like in many action movies, an “energy use crisis” was quietly resolved, with no one, either the workers on the production line, the customers in the shopping center, or the residents at home, noticing anything unusual. And the behind-the-scenes “operation center” for this regulatory process was the large screen in the Energy Operations Center of State Grid Pinghu Power Supply Company, which displays 24-hour energy consumption data from local automotive companies.

This large screen showcases the data analysis module for monitoring automotive companies’ energy consumption. Developed by State Grid Pinghu Power Supply Company on the VPP platform utilizing big data, this module revolves around “aggregation” and “control” and amalgamates data pertaining to energy storage and biogas power generation throughout

Pinghu. It employs a four-tier management system for each company based on their position within the industry chain and their energy consumption. As a result, the staff at State Grid Pinghu Power Supply Company can tailor energy assurance strategies for each enter- prise, leveraging real-time energy data and sophisticated data matching algorithms to meet their specific requirements.

The module also analyzes the enterprises’ historical energy consumption and benchmark data to offer a variety of energy efficiency improvement recommendations through energy consumption reports. It continuesly shapes government policies aimed at facilitating the establishment of new photovoltaic and energy storage facilities to bolster the VPP’s load regulation capabilities. While ensuring the fulfillment of their fundamental power requirements, State Grid Pinghu Power Supply Company also provides incentives for commercial and industrial enterprises with excess energy capacity to share electric power with other enterprises through subsidy programs. This collaborative approach has improved energy utilization throughout the entire industry chain.

Since the launch of this module, even when electricity consumption temporarily doubled due to a surge in orders, the automotive companies in Pinghu have never halted their production. This “peakshaving and load shifting” solution can reduce electricity expenses by RMB 77,000 within 30 days for local automotive companies. Additionally, over RMB 1 million in subsidies has been offered to those participating in demand response schemes. So far, the local automotive industry has achieved a 5.2% year-on-year increase in output value. The VPP has not only ensured uninterrupted electricity supply for enterprises but has also reduced their energy costs, thereby enhancing the overall competitiveness of the local auto- motive industry chain.

Expanding the VPP across the region and embracing the energy era powered by digital technology

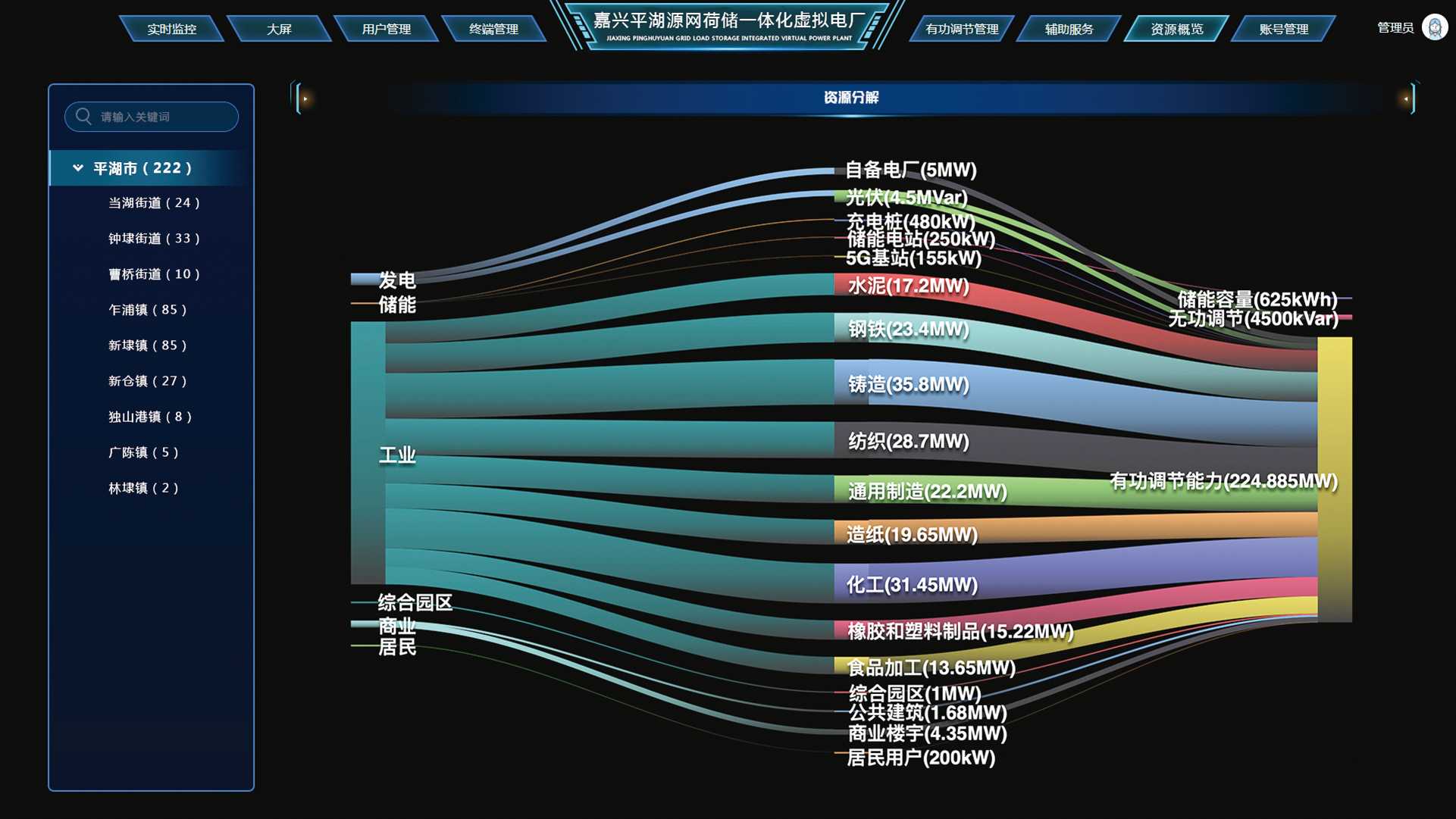

After more than three years of development, State Grid Pinghu Power Supply Company’s virtual power plant has progressively expanded its range of controllable load categories. Its applications are no longer limited to industrial enterprises like automotive manufacturers but have extended to various user types across the entire county, including those involved in distributed power generation, energy storage, industrial development, comprehensive parks, and commercial sectors. In 2022, with the establishment of Zhejiang’s first county-level power load management center in Pinghu, all commercial and industrial users in the county have come under the management of the center. The VPP, serving as a diligent “steward” for the diverse businesses in Pinghu, continually searches for scattered electrical resources throughout the county to meet the daily energy needs of all “family members”. Diverse types of terminals, be they for generation, storage, or conversion, have all been integrated into this energy network, further expanding its resource pool.

Consider the example of air conditioning in a commercial complex again. Due to global warming, summer temperatures in Zhejiang Province, situated on the southeastern coast of China, have been increasing annually. Air conditioning has become indispensable for local residents, making the summer air conditioning load a significant factor in balancing power supply and demand.

Based on its VPP, from November 2022 to May 2023, State Grid Pinghu Power Supply Company installed flexible control devices for central air conditioning systems in all eligible government offices, hotels, and commercial complexes. These devices can regulate up to 22,700 kW.

In 2023, Zhejiang experienced its highest historical summer average temperatures. This created a valuable opportunity to test the capabilities of the VPP. State Grid Pinghu Power Supply Company conducted a total of 9 air conditioning flexible control drills across the county. Without any discernible impact on the indoor residents, the VPP effectively achieved an average load regulation of 15,000 kW, with the maximum load reduction reaching 39.5%. In essence, by adjusting the central air conditioning temperatures county-wide, the VPP managed to save 15,000 kW of electricity, yielding substantial cost savings for public building operators.

As of now, State Grid Pinghu Power Supply Company’s virtual power plant has the capacity to regulate 242 MW of electricity, including 17.1 MW for peakshaving, 7.2 MW for load shifting, 0.3 MW for reactive power regulation, and 15.8 MW for interruptible services. This capacity effectively meets power demand during regular summer load peaks, and translates into savings of approximately RMB 960 million in land resource and utility corridor investments. For every 100 hours of utilization, the VPP can generate 24,200 MW of electricity, resulting in annual savings of 9,800 TCE and a reduction of 27,600 tons of carbon dioxide emissions. This eco-friendly and cost-effective virtual power plant benefits multiple stakeholders, transitioning the once “disorderly” power supply into a truly “orderly” system.

Today, the VPP model pioneered in Pinghu has proliferated throughout the entire city of Jiaxing, Zhejiang province. In the days ahead, State Grid Pinghu Power Supply Company will continue to explore controllable load resources on the demand side,. It will employ innovative administrative, technological, and economic strategies to encourage more businesses are partaking in this “load shifting and peakshaving” cooperative effort. This collective initiative will significantly contribute to the advancement of State Grid’s ambition to develop an inter- nationally leading energy internet with Chinese characteristics. And then, the new electric power systems based on new energy sources will eventually illuminate every household, fuel production lines across various industries, enhance people’s quality of life, and propel the progress of regional, national, and global development.

Back

to top

Back

to top