On June 13, 2024, the 30th Sino-European CSR Roundtable Forum, organized by amfori and China Sustainability Tribune, was held in Beijing.

Focusing on “Intelligent Supply Chains for an All-Win Future,” the forum invited sustainability experts, industry association representatives, brands, and suppliers to share the latest regional policies, ideas and practices for building partnerships in intelligent supply chains, and offer insights into higher quality and more efficient supply chain solutions for brands and suppliers. The forum attracted nearly 300,000 visits online and offline.

Getting the Big Picture of Intelligent Supply Chains

“The intelligent supply chain can help the companies master real time visibility, proactively respond to disruptions throughout the supply chain, and enhance resilience.” In his welcoming address, Richard Teply, Head of Business Development and Network, amfori, cited relevant European legislation and amfori's support for sustainable trade and sustainable supply chain, and shared his understanding of the forum's theme.

He highlighted the significance of collaboration in supply chain development and said that, the value from an intelligent supply chain is derived by developing maturity in selecting digitally driven capabilities that place focus on the customer and continuously innovate, build competitive advantage, and improve business, and societal outcomes. With an intelligent supply chain, companies leverage modern technologies to collect data and develop insights to better optimize their supply chain. This can save on costs, increase profitability, increase their speed to customers, and get ahead of their competition. amfori believes that businesses can play a crucial role in driving a positive impact on the planet and contribute to prosperity.

During the keynote speeches, Liu Dacheng, Vice President of the Internet Industry Research Institute, Tsinghua University led the participants to gain insights into the supply chain from a global perspective. Immersed in the global supply chain development from the unified measurements and the Grand Canal made thousands of years ago, the Age of Discovery hundreds of years ago, to the industrialization, informatization, networking, and digitization in modern times, Liu concluded that at the core of the changes is that optimized allocation of production factors drives the efficiency of supply chain operations.

“In the 21st century, competition is no longer between companies, but between supply chains.” By citing the quote from Martin Christopher, a renowned expert in the realm of global logistics and supply chain, Liu elaborated that companies must pay attention to supply chain management, especially the role of computing power and artificial general intelligence (AGI) in the development of supply chains, which may lower energy consumption and costs dramatically. In a nutshell, the digital transformation of industries will propel the development of sustainable supply chains.

Pooling the Power of Industries to Drive Supply Chain Transformation

As an essential livelihood sector, the textile industry is a key player in global green development. Zhang Wenya, Head of Corporate Partnerships for Sustainable Innovation Projects, Social Responsibility Office of China National Textile and Apparel Council introduced the LCAplus, a digital traceability platform for the cradle-to-grave carbon footprint of textiles.

The platform integrates seven core functions of product management, supply chain management, comparative analysis management, report management, information disclosure, database administration, and process chain management. Based on the Life Cycle Assessment (LCA), the platform attaches credible carbon labels to products. As of April 2024, it has accomplished the on-site data collection and evaluation of 33 end-user brands and more than one hundred end products across the entire supply chain, reaching 173 suppliers and covering 13 types of fibers.

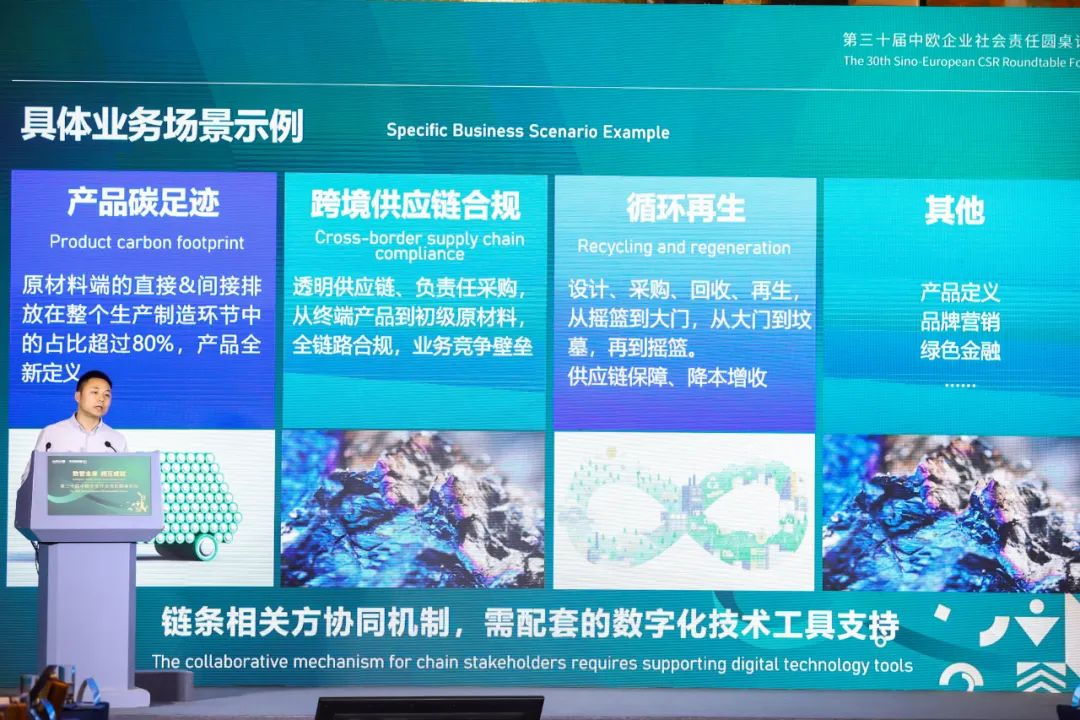

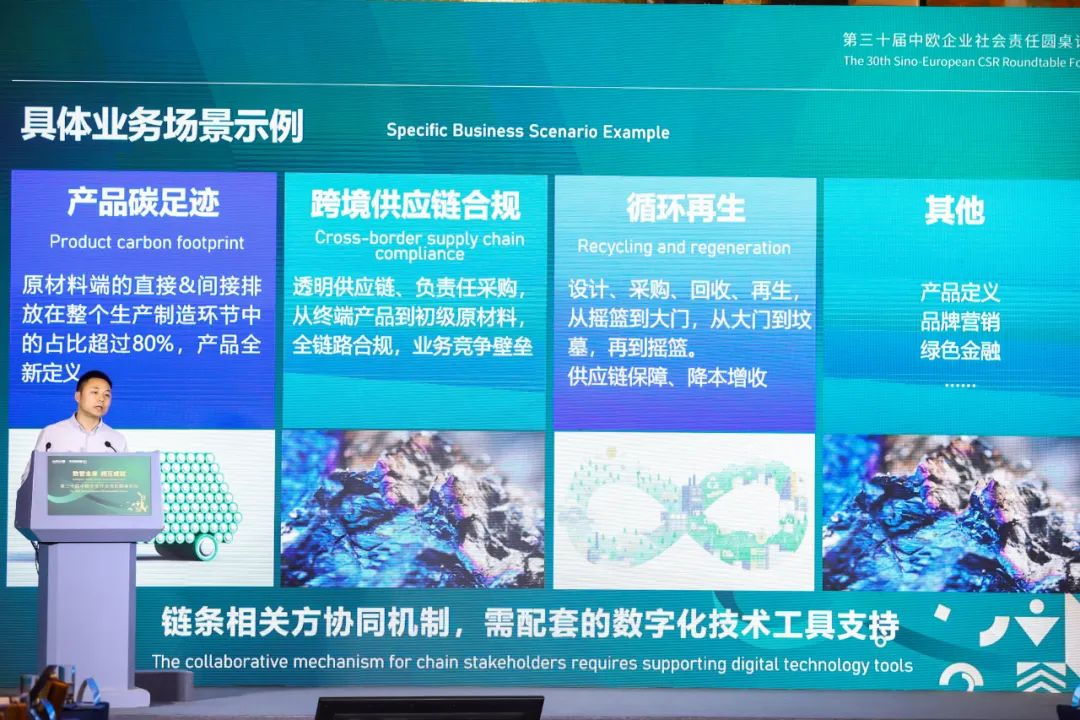

Automobiles are intricately integrated products that cover a broad spectrum of industries and a lengthy value chain. Dai Qibo, Assistant General Manager of digital technology sector, Zhejiang Geely Holding Group, shared his insights with the topics “the Pivotal Role of Digital Intelligence in Transformation, Upgrading and Reconstruction of Supply Chain”.

He pointed out three main challenges facing the digital collaboration of the industrial chain. First, it’s hard to ensure end-to-end responsiveness and coordination across the vast supply chain. Second, the digital management competencies and approaches among enterprises in the industrial chain vary significantly. Third, domestic and international regulatory requirements are dynamically updated and increasingly stringent.

How does Geely Holding respond? Geely Holding develops a unified traceability network that underpins digital collaboration across the industry chain, including raw material traceability and circular manufacturing scenarios. The success hinges on compliance, collaboration, and technologies. Along the journey from 0 to 1, it’s imperative to address fundamental demands and ensure compliance before production and exporting. Moving from 1 to 10, collaborative sharing is the key as the lengthy automotive industry chain necessitates a joint effort from all stakeholders. The scaling from 10 to 100 is powered by digital technologies, coupled with shared information and technologies, and consistent data and standards.

Companies Take the Initiative to Navigate Complex Supply Chain

Lars Ringtved Nielsen, Compliance and Quality Director, JYSK, introduced JYSK’s “Digitised Due Diligence for Green Supply Chain: A Win-Win Strategic Choice”. JYSK itself does not engage in production, but it conducts strict audits of all suppliers and business lines and strengthens follow-up and monitoring, which are performed with JYSK’s robust data tools and based on global sustainability initiatives and certifications, such as, amfori BSCI, amfori BEPI, OEKO-TEX® STANDARD 100, FSC, Better Cotton, GRS…

In the subsequent Q&A session, the guests had a heated interaction with the attendees. Regarding the question about business going global, Liu Dacheng illuminated that companies should start from multiple aspects including procurement, manufacturing, and sales, and should understand, comprehend, and embrace international standards first. Dai Qibo proposed that the crux of cross-border supply chain compliance lies in grasping the common points among diverse standards in China and abroad while boundary ambiguities can be ironed out through communication. Richard Teply said that China is really proactive in driving sustainable development with a succession of related national policies rolling out, which is a competitive advantage for Chinese companies to go global and also demonstrates that China is well positioned.

Working Together

To Build Intelligent Supply Chains for an All-Win Future

In the panel discussion, panelists shared their insight into how to achieve all-win results in building intelligent supply chains.

Bruno, Product Manager Environment, amfori, said that data quality is at the core of digitalization. At amfori, partnerships through the membership network and the application of standard tools assure the reliability of data. He also noted that information transparency and confidentiality are of equal significance. Moreover, he particularly emphasized the importance of communication and collaboration. Problems can be uncovered by communication and listening, and can be addressed through openness and collaboration, which will create a virtuous cycle and allow all stakeholders to grow.

According to Han Tingting, Head of Sustainability &CSR at Royal Golden Eagle China, the Royal Golden Eagle (RGE) is committed to zero deforestation, zero forest degradation, and zero forest conversion in business operations and the supply chain. To better fulfill its commitment and navigate its complex global supply chain, RGE procures raw materials with forest certification and carries out due diligence on the supply chain to identify and mitigate the risk of deforestation in the supply chain. Meanwhile, together with supply chain partners, RGE promotes forest certification in the procurement area for better responsible forest management throughout the supply chain. Next, RGE looks to leverage digital technology and platforms for better supply chain management, continuously enhancing the traceability and transparency of the supply chain.

Through the study of the digitization of companies within the Suzhou Industrial Park, Wu Xuejun, Vice General Manager, Sungent Urban Development Co., Ltd,Head of Suzhou Industrial Park Urban Development Research Institute, observed four major trends. First, digital capabilities are increasingly upgraded. Second, the enterprise digital application scenarios are continuously expanding. Third, digitalization and going green are synergized. Fourth, companies within the park are encouraged by the government and the management committee to go digital and intelligent, playing the mainstay role to catalyze cost reduction and efficiency enhancement.

Yu Xianghai, Consulting Director of GoldenBee Consulting, affirmed that digitalization brings tremendous potential value to the sustainability of the supply chain, with three pronounced features: efficiency, accuracy, and development. With the advancement of intelligence and digital technologies, an increasing number of companies will be connected to integrated platforms, and all scales of companies will embrace broader prospects.

Yu Zhihong, President and Editor-in-Chief of China Sustainability Tribune, summarized that digitalization and intelligence are a trend of the times and we are all in it. The intelligent supply chain will bring myriad opportunities, such as more reliability, higher synergy, stronger security, and more development chances. There are also many challenges, such as the reliability of data, the alignment of standards, and the collaboration of enterprises. Today’s sharing and discussion have also given rise to some feasible solutions, such as communication, cooperation, and better transparency.

Scan to watch the replay of our event

The Sino-European CSR Roundtable Forum

As a professional and practical communication platform and channel for corporate social responsibility, the Sino-European CSR Roundtable Forum has focused on topics such as " carbon reduction partnership in supply chains," "ESG and supply chain management," and " women empowerment in global supply chains." These discussions have consistently promoted the sustainable China-Europe supply chains.

Since 2008, the Forum has been successfully held for 29 times, with 240+ Chinese and European speakers sharing their views, 2,400+ representatives participating in the Forum in-person, and 100,000 to 300,000 representatives attending on-line each session, covering more than 10 countries in Europe, North America and Asia. The forum has shared the insights of guest speakers, launched research reports, and released corporate practices, shaping a significant partner network and vast pool of experience, and creating a powerful engine for the sustainable supply chains.

Back

to top

Back

to top